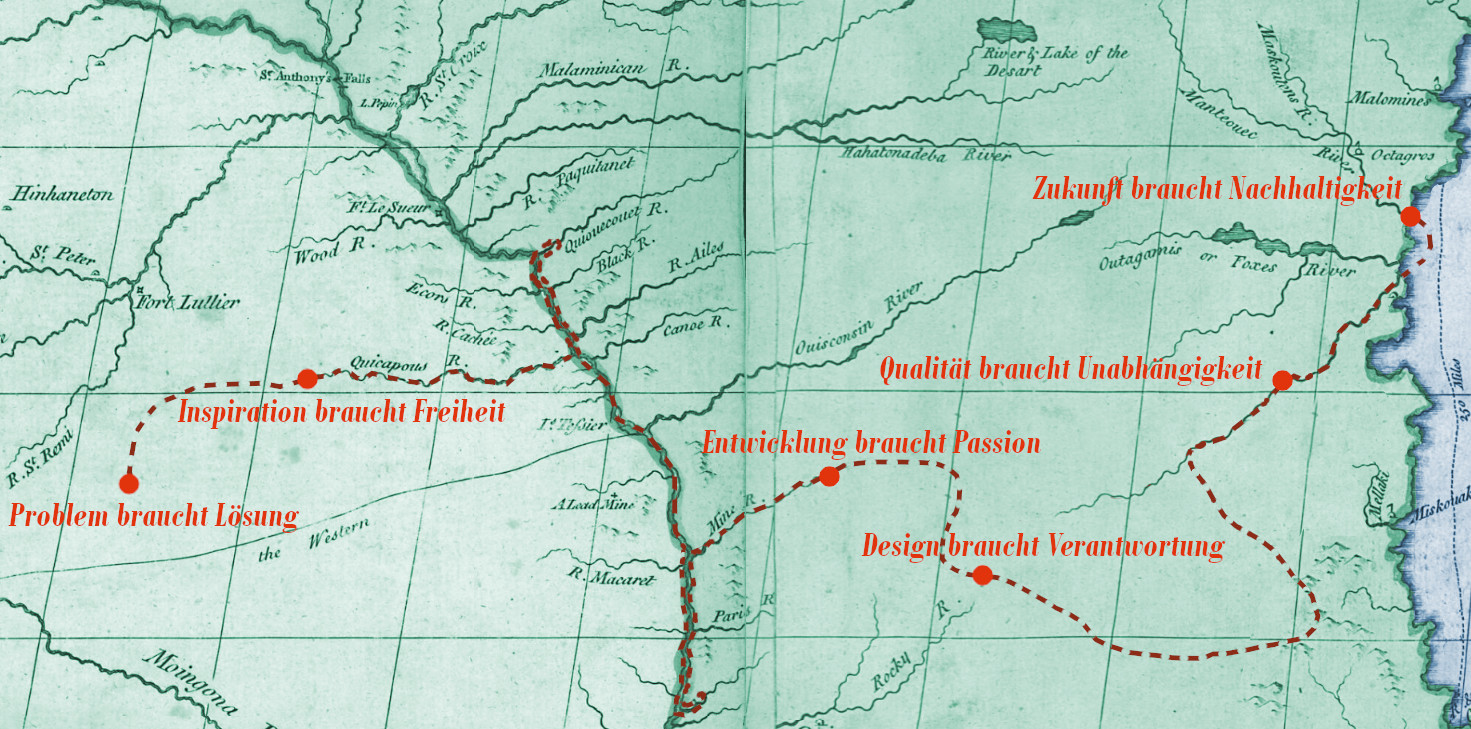

Vision: Inspired developments design the quality of the future

Services

Training

Compentent training for the following topics:

- Polymers, Properties and Processing

- Biopolymere: Is this the future?

- Behaviour of plastic components (mechanically, thermally)

- Wet cooling tower behavior and thermodynamics

- Selection and maintenance of components for wet cooling towers

Assessment

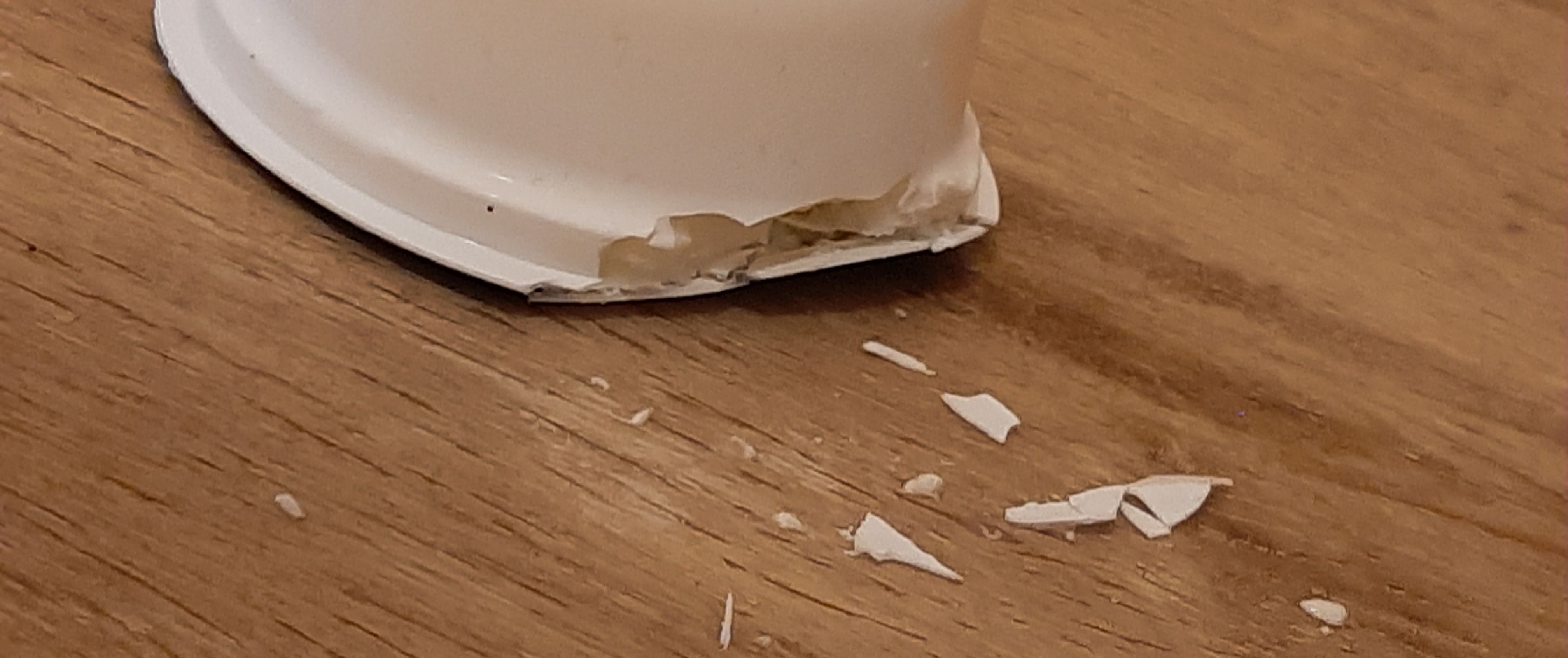

Independant assessment of

- plastic processing and products

- plastic components for cooling towers and other industrial applications

Advice

Do you have a technical question in the above-mentioned environment, where you need competent and neutral advice? With the background of sucessful implemantation of ISO 50001:2018 I also can help you with the energy reduction and monitoring of your plastic processing

Design and specification support

You want to plan a new wet cooling tower or technically check or overhaul an existing one? I can support you in this procedure.

I can support you with your plans on evaporative cooling, too.

Data analysis

I have a lot of experience in evaluating and amounts of big data and therefore can also help you with yours. I also can help with the documentation.

About me: Dr.-Ing. Nina Woicke

I have more than 20 years of experience in the field of plastics science. A major focus for me is analysis and modelling of the mechanical properties of thermoplastics, in particular the relationship of time- and temperature- and stress-dependent behavior.

In addition, I have been a process engineer since 2002 with broad knowledge in the field of various thermal (wet cooling), physical (washer/stripper) and biological (wastewater treatment) processes.

I started my professional career in an ISO 17025 accredited examination institute, where I specialized in different methods of plastics testing and damage analysis. Quality-ensuring processes such as documentation of information and process-oriented work have been my firm companions ever since.

After my PhD, I changed into industry. Through my development work in a manufacturing company, I have gained very thorough knowledge of the extrusion of PP and PVC as well as injection moulding of PP. I led projects worldwide in the field of digitization in production and the use of biopolymers.

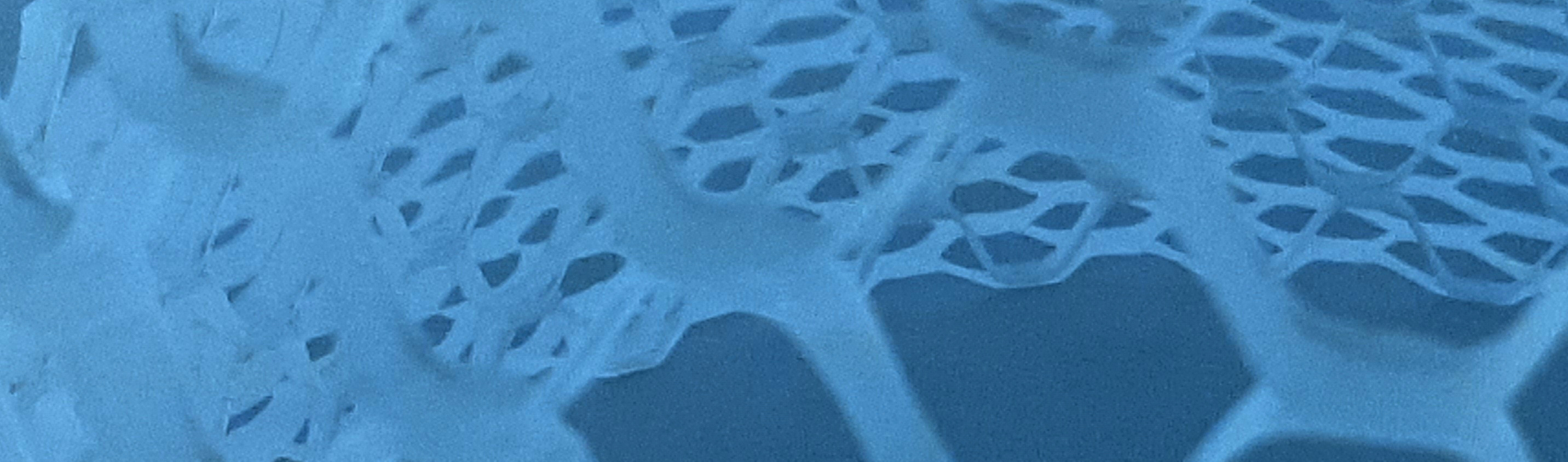

In process engineering, my main emphasis can be found in the field of wet cooling technology.

I have contributed to various committees (EUROVENT, VGB, CTI, VDMA) on topics such as legionella in cooling systems, the performance of droplet separators, the design and maintenance of cooling tower components and energy efficiency.

Memberships

CV

Publications

Zaorski, A.; Woicke, N.; Evans, J.: Parameter Study of Mechnically Loaded Bottom-Supported Cooling Tower Fills Packs, TP25-11, CTI 2025, USA

Woicke, N.: Sammlung zur Nachhaltigkeit für kleine (nicht berichtspflichtige) kunststoffverarbeitende Unternehmen, Whitepaper, 9/2024, online, Germany

vgbe: Planung und Betrieb von Kühltürmen, VGBE-S-135-00-2024-05-DE, Standard, 5/2024 , Essen, Germany

Woicke, N.: Carbon Footprint Influencing Factor Analysis of Polypropylene Fill Based on Literature Data, TP23-07, CTI 2023, USA

Ziegler, D.; Woicke, N.; Evans, J. : Lab Evaluation of Fill Component Flammability, TP23-15, CTI 2023, USA

Woicke, N.: FEM Concept Study on the Anisotropic Mechanical Behaviour of Cooling Tower Film Fills, TP22-21, CTI 2022, USA

Woicke, N.: Deformation Behavior of Cooling Tower Fills, TP19-15, CTI 2019, USA

Woicke, N., Dierenfeld, D. : Time and Temperature dependant Deformation Behavior of PP Fills, TP17-09, CTI 2017, USA

Woicke, N., Dierenfeld, D. : Mechanical Behavior Of Polymer Fills, TP16-01, CTI 2016, USA

Dahm, M.; Woicke N.: Modular Splash Fill, TP15-03, CTI 2015, USA

Woicke, N.; Müller M.; Puschmann, M.: Higher Mass Transfer Performance: Improvement of Wettability of Plastic Packings During the Operational Time, CHEManager Europe 11/2012

Woicke, N.; Mayer, E.-J.: Wirschaftlichkeitsbetrachtung von typischen Kühlturmeinbau-Materialien hinsichtlich der CO2-Bilanz bei der Herstellung, 9. VDMA Kühlturmtagung 11/2011, Frankfurt, Germany

Alig, I.; Lellinger, D.; Wenzel, M.; Böhm, F.; Woicke, N.; Rodriguez Sánchez, A.: Verfolgung und Simulation der Härtung von Epoxidharzen: Vorhersage reaktionsinduzierter Spannungen, 11. Kolloquium Klebetechnik 22.-23.2.2011, Frankfurt, Germany

Woicke, N.: Tailored polymer testing for improved simulations, In: Polymers - Opportunities and Risks I: General and Environmental Aspects, Springer Science & Business Media, 2010

Woicke, N.: Brandverhalten von Kunststofffüllkörpern, 8. VDMA Kühlturmtagung, 3/2009 , Frankfurt, Germany

Woicke, N.: Flame Retardance of Polymer Film Fills, TP 09-14, CTI 2009, USA

Woicke, N.: Polypropylen, Thermo-Mechanische Eigenschaften; In: Domininghaus - Kunststoffe: Eigenschaften und Anwendungen (Polymers: Properties and Applications), Springer, 2008 & 2012

Eyerer, P.; Kroh, M.; Woicke, N.: Selektives Lasersintern von Hochleistungspolymeren mittels Nd:YAG-Laser., In: Entwicklung und Erprobung innovativer Produkte - Rapid Prototyping. S. 430-443, Springer, 2007

Woicke, N.; Geier, S.; Göschel, U.; Eyerer, P.: Influence of Modern Nucleating Agents on the Crystallization of PA6 PPS-22, 3.-6. Juli 2006, Yamagata, Japan

Woicke, N.; Kroh, M.; Eyerer, P.: Rapid Prototyping of PEEK Parts by the Means of Laser-Sintering, PPS-22, 3.-6. Juli 2006, Yamagata, Japan

Woicke, N.; Eyerer, P.: Finite Elemente Simulation of the Curing process of Epoxy Resins, PPS-22, 3.-6. Juli 2006, Yamagata, Japan

Woicke, N.: Viskoelastizität von Polypropylen im Glasübergang, Doktorarbeit, 2006, Stuttgart, Germany

Woicke, N.; Wagner, T.; Eyerer, P.: Selective Laser Sintering of High Temperature Resistant Thermoplastic Polymers, PPS21, 06/2005, Leipzig, Germany

Woicke, N.; Wagner, T. ; Eyerer, P.: Carbon Assisted Laser Sindering of Thermoplastic Polymers, ANTEC, 05/2005, Boston, USA

Keuerleber M.; Woicke N.; Raisch; S.R.; Eyerer, P.: Temperature and Strain Rate Dependent Simulation of High Speed Tensile Tests of I-PP, Journal of Polymer Engineering. Volume 25, No.5, 2005

Rüb, G.; Woicke, N.; Hegemann, B.; Eyerer, P.: Messverfahren zur Bestimmung der Querkontraktion, 19. Stuttgarter Kunststoff-Kolloquium, Stuttgart, 9.-10. März 2005, Stuttgart, Germany

Woicke, N.; Wagner, T.; Eyerer, P.: Rußunterstütztes Lasersintern von Thermoplasten, 19. Stuttgarter Kunststoff-Kolloquium, Stuttgart, 9.-10. März 2005, Stuttgart, Germany

Woicke, N.; Keuerleber M.; Hegemann, B.; Eyerer, P.: Three-dimensional thermorheological behavior of isotactic polypropylene across glass transition temperature, Journal of Applied Polymer Science, Wiley, Nov 2004

Blumenstock, T.; Woicke, N.; Eyerer, P.: Measuring and modeling the rheological data of Diglyciylether of bisphenol-A during polymerization for finite element analyses, Journal of Applied Polymer Science, Wiley, 11/2003

Keuerleber, M.; Woicke, N.; Eyerer, P.: Simulation des Temperatur- und dehnratenabhängigen Materialsverhaltens bis zur Streckgrenze im Schnellzerreißversuch, 18. Stuttgarter Kunststoff-Kolloquium, Stuttgart, 19. - 20. März 2003, Stuttgart, Germany

Woicke, N.; Blumenstock, T.; Eyerer, P.: Temperaturabhängige Polymerisationsschwindung von DGEBA unter Berücksichtigung der Reaktionskinetik, 18. Stuttgarter Kunststoff-Kolloquium, 19.-20.März 2003, Stuttgart, Germany

Keuerleber, M.; Woicke, N.; Möginger, B.; Eyerer, P.: Temperature and Strain Rate Dependent Simulation of High Speed Tensile Tests Before Yielding, PPS 19, 1/2003, Melbourne, Australia

Blumenstock, T.; Eschl, J.; Moranchel-Caballero, S.; Woicke, N.; Eyerer, P.: Aushärtungsvorgänge von Duroplasten - Kennwertermittlung, Modellierung, Simulation, 17. Stuttgarter Kunststoff-Kolloquium, Stuttgart, 14.-15. März 2001